UWB in Manufacturing: Smart Factories through UWB

2025-03-25

Geoplan’s UWB positioning RTLS solution for smart factories interlinks the 5Ms of manufacturing (Man, Machine, Material, Method, and Measurement). By collecting, monitoring, and managing real-time operational data, Geoplan enables production and quality management, leading to smarter manufacturing plants.

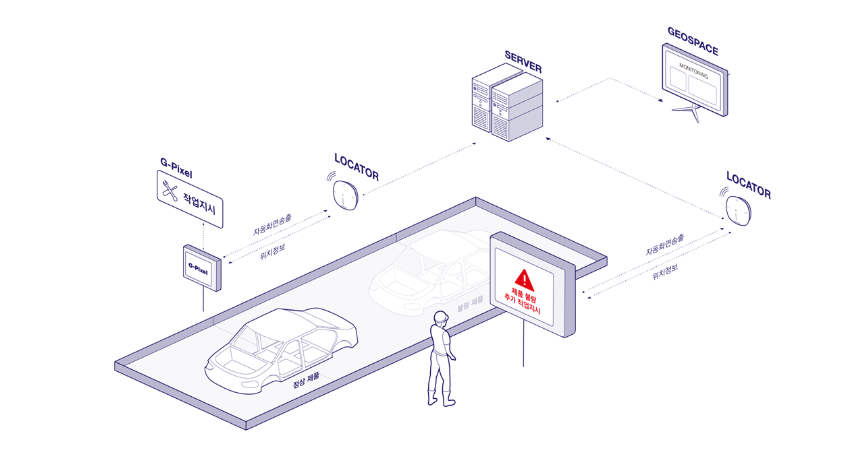

Digital Work Instructrion

Geoplan’s UWB g-pixel EPD tags enable factories to minimize work errors and enhance real-time task awareness. These tags, located in work zones, automatically update displayed task statuses as employees complete their work, improving process visibility from assembly to quality control.

Source: Geoplan

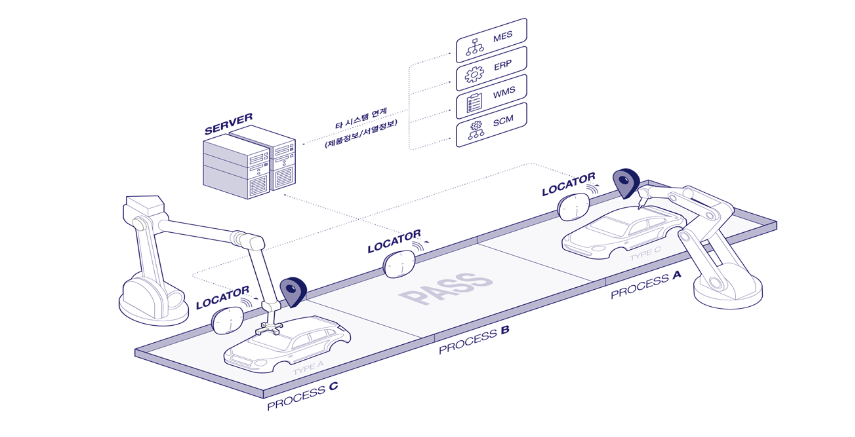

Flexible Auto-Production

Tags are attached to all production items to enable flexible production line tracking. Each tool in the work zones automatically completes tasks on the item, and all the completed tasks are recorded on the tag as both tools and items have UWB tags attached to them which gets matched to the task on RTLS system.

Source: Geoplan

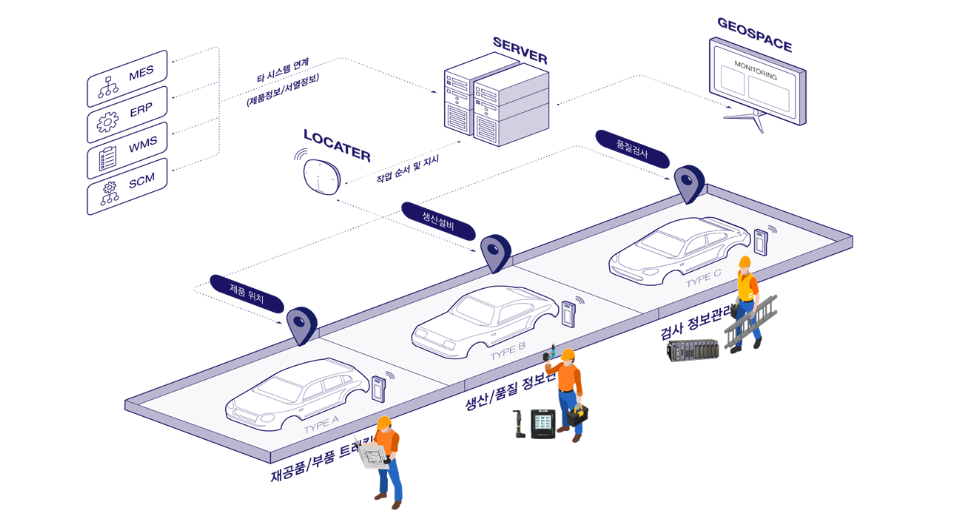

Productivity & Quality Management

Location-based smart sensors can secure production information matching, respond to variability during production, and improve quality and productivity by tracking re-finished products/parts, guaranteeing production quality, and managing inspection results.

Sources: Geoplan

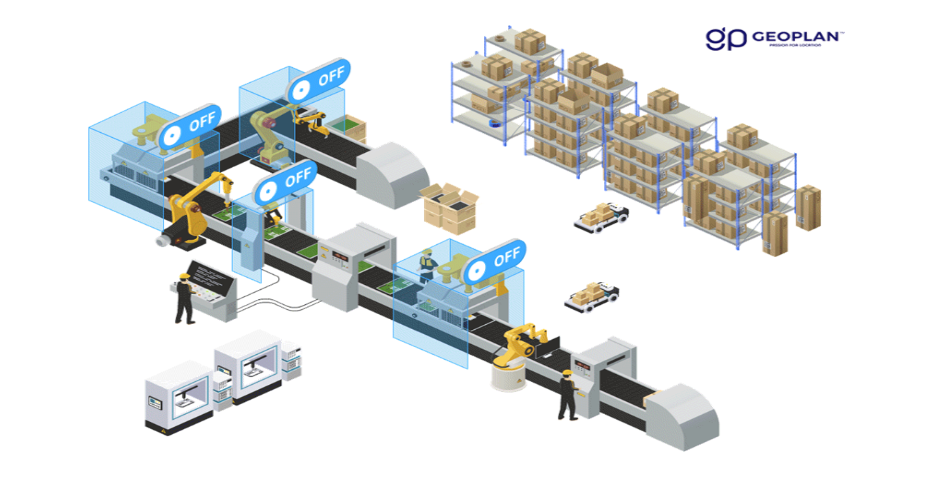

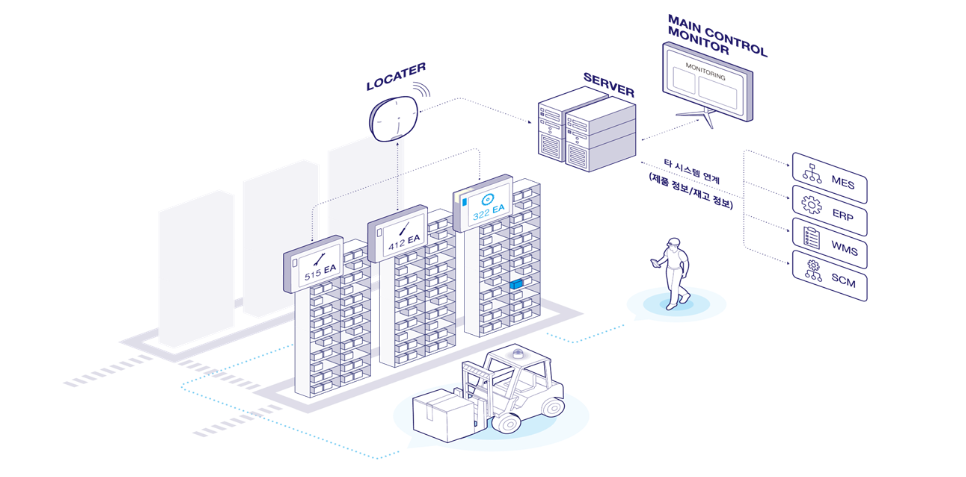

Smart Packing

Smart Packing system allows users to visualize logistics location and inventory in real time with an electronic indicator based on wireless precise positioning, and implements a smart picking system from incoming and outgoing management to first-in-first-out management.

Source: Geoplan

태그

ANTICOLLISIONG-PIXELLOGISTICSSMARTSAFETYUWB

Blog